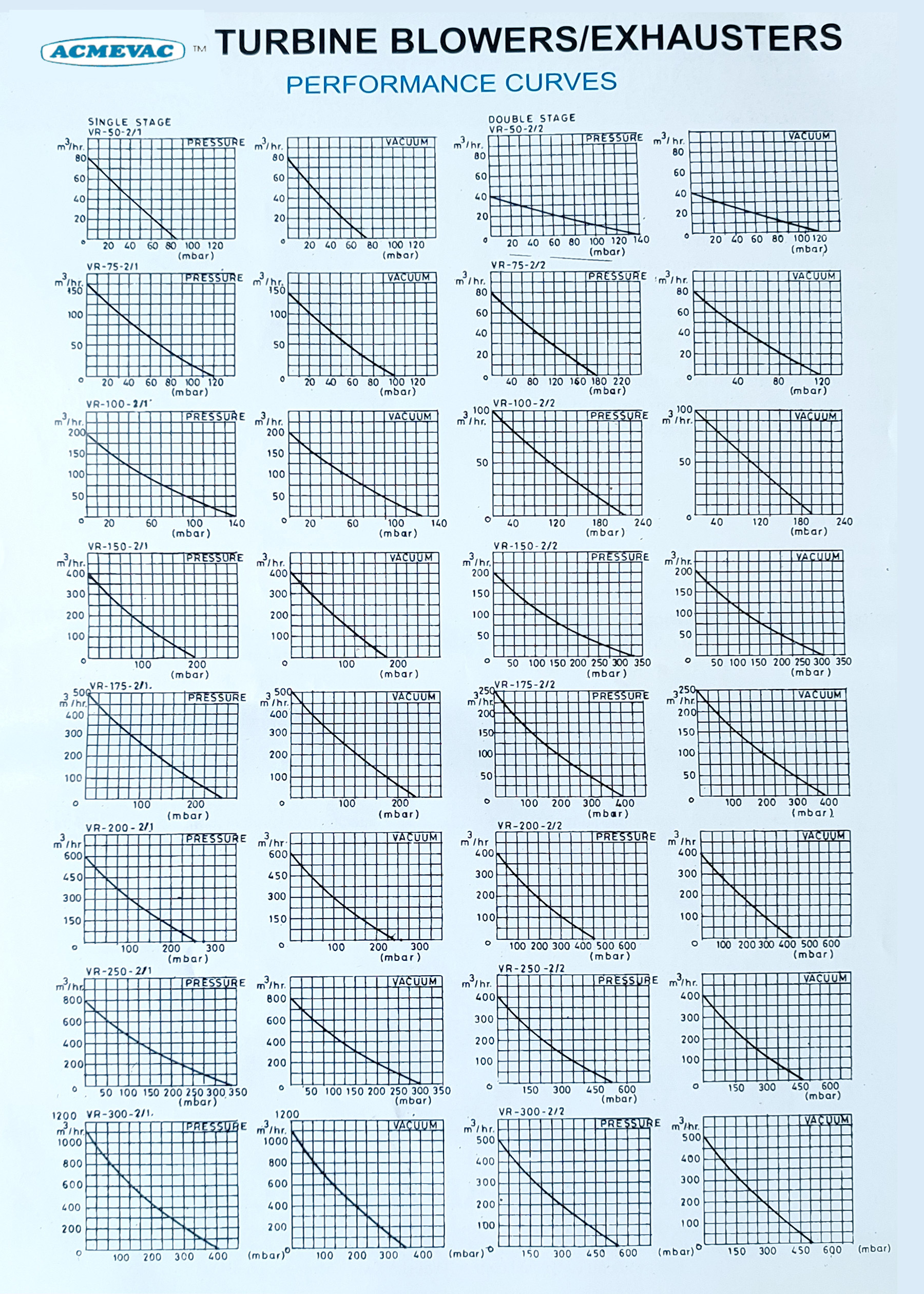

Turbine Blowers

Overview

vacuum pump. It is also known in other names such as regenerative blower, vortex blower and side channel blower. All of the names describe the basic principle of operation of the blower. The blower consist of an dynamically balanced impeller mounted directly on a motor shaft and is rotated at a high speed of about 3000 R.P.M. The impeller revolves in a stator-cum-compression chamber having very fine clearances between them. Both of the openings for suction & pressure are located on the outer periphery of the stator to reduce impedance to the air flow thereby developing the required vacuum and pressure levels. The turbine blower is, in effective, a multi stage compressor with each regeneration of the air becoming another "Stage". The basic construction of a turbine blower means that the only moving part is the impeller.